Mixture Toeboards how to do it...

This mixtureboard is inspired by Casavant's work, though I expect other builders have simular designs.

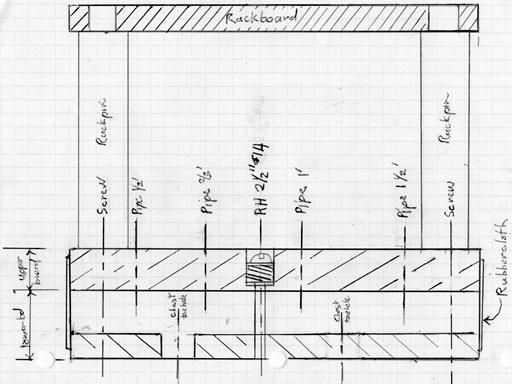

Making the mixture toeboard is fairly simple. You start with two boards: a 1-1/4" (32mm) thick bottom board, and a 3/4" (19mm) upper board. You drill the bottom holes into the bottom board to match the chest holes. Don't forget a couple of locating dowels.

Then with a dado blade in the radial arm saw, cut the note channels into the bottom board. These dados are 7/8" deep (21mm) and at least the width of the bottom holes they match up with. If you've got room, bigger is better. Having the pipes on a large, common dado channel guarentees the speak simultaniously. The Dado channel also acts as a shock absorber against the explosive pouch action, improving speech. It is also clains that pipes that share a common wind channel lock in phase and say in tune and blend better.

Next, nail the rack and upper board together. Line up with the dados, and spot the pipehole locations (and rackpins!). Then take apart and drill all the pipe wind holes, countersinks and rack holes. Deburr the lower opening of the pipehole.

To complete, Glue and clamp the upper and bottom boards together; be sure they are flat. Then joint the edges clean and glue strips of rubber cloth to both edges to seal the dado. Finally, seal the channels by flooding them with shallac or sanding sealer. If you don't seal, you'll get runs from air blowing thru the grain.

You'll need gaskets on the underside of the mixtureboard to seal against the chest. The photo example used thin cork, though I prefer thick, soft leather. You should have a wooden dowel at each end, to keep the holes aligned.

Screws and rack pins are typically spaced about 12' apart, along the mixture board. There should be enough of them so that someone can stand on the rackboard; because some idiot will... The rackboard sould be of good plywood, not solid wood, for the same reason.

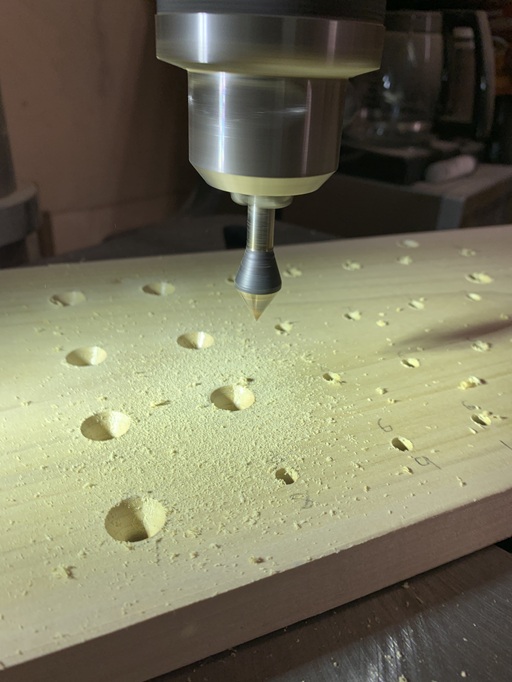

For drilling the holes for the pipes use the drilling chart for mixtures. The chart is a little complicated, but if you can't figure it out, you probably shouldn't be using power tools...

When laying out the pipes if things get crowded, you can zig-zag the rows for more room. Mixture pipes will blend and draw in tune better if the pipe bodies of the same note and close together. But don't crowd the mouths, nor face moths into each other.

For the holes in the bottom of the toeboard, connecting to the chest use the following drill sizes. These should be considered the minumum size. For large mixtures consider using two feed holes/pouches in the bass.

- # 1 - 32 drill 5/8" (16mm)

- #33 - 40 drill 1/2" (13mm)

- #41 - 61 drill 3/8" (10mm)

Mixtures, Tuning

Mixtures can sometimes be very difficult to tune. Some voicers do sloppy work on Mixtures, because they think that with four pipes speaking nobody will hear the difference. But mixtures require the very best voicing. Overblowing, dirty, off-speech pipes are impossible to tune. What I do it that case, is sitdown and go thru every pipe, blow it by mouth, and fix it.

The toe countersinks may be too flat; don't use a screw countersink. I have special, 60 degree countersinks for trebles, to ensure they fall into their holes; should they get knocked up when the tuner flattens them.

I have two countersinks. The first has an outside diameter of 20mm which I use for toeholes in the chest that are 11 to 8.1mm diameter. My smaller countersink has a outside diameter of 15mm which is used for 8mm and smaller. I drill the countersink all the way in to its shoulder. I use a normal 45 degree burn stone for larger than 11mm.

Another cause of tuning trouble is bad winding; there are several causes. The pouch hole or cross-channel dato could be too small. I always overside everything so all the pipes get a full flush of air. Then, should there be a little leakage somewhere, it won't matter. Sometimes the racking is too tight and the pipes can't settle into their holes. Treble pipes should be loose in the rack, they should rattle when shaken.

Mid-sized countersinks are done with a burnstone.

The very largest countersinks are done with a router bit with a ball bearing.