St Pauls Presbyterian Organ, Simcoe, ON.

I heard a rumour, that in 1920's St Pauls church was sitting on a huge bequest of money. With the unknowns of Church Union pending in 1925, the Presbyterians feared losing control of that money. So they decided to invest it in a new organ. Because they had an awful lot of cash, they bought an awfully big organ. Also, in 1920, St James United Church had just bought a big new three manual organ, so St Pauls had to have four manuals...

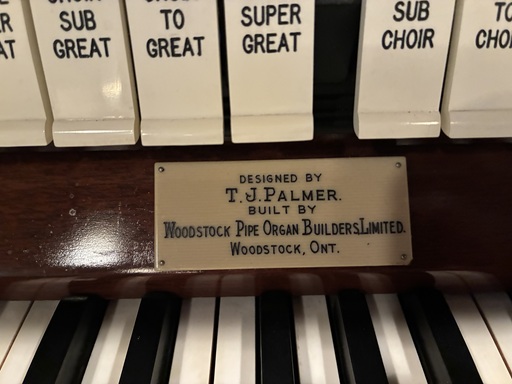

The New Organ, Console Nameplate

Fortunately, we have a copy of the original organ contract. For the church, it was signed by the church treasurer, Mr L.C. Gibson. Lou Gibson became the organist of the new organ (and remained the organist until the 1970's), so one would presume he played an active role in its purchase. Though not a classical musician, he was a very talented player and frequently and brilliantly improvised his hymn accompanizations. As a teenage organist, I went to St Pauls several times just to hear him. In fact, I served as interm organist for a year, after Lou retired.

The church hired Mr T.J Palmer, from Ottawa, as organ consultant. He was also the consultant for the biggest church organ in Canada, the big Casavant in St Pauls Bloor St, Toronto, so must have been respected in his field. He later became a salesman for Woodstock Organ Co. The organ contract, which Palmer wrote, was very detailed about the pipes, so Mr Palmer must have fancied himself a organ pipe tonal expert. As some of Palmer's ideas were idiocratic, Casavant would include his name on the organ nameplate, to ensure Palmer got the credit/blame due him.

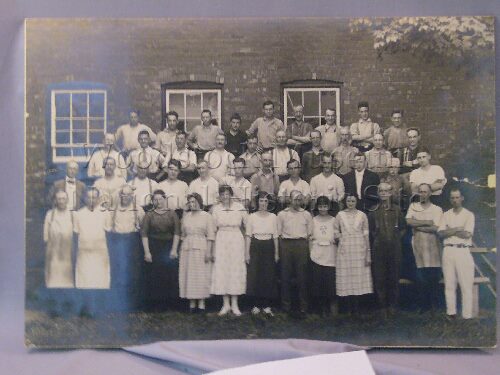

Woodstock Organ Company, 1926

The photo shows the original staff who built the St Pauls organ. At the time, Woodstock Organ Company was only a few years old. But it was comprised of the staff and equipment from the recently closed Karn-Warren Organ Company/Warren Organ Company. The Warren legacy stretched back almost 100 years, making some of the finest Canadian organs ever built.

The St Pauls organ was one of the largest organs Woodstock built, with four keyboards, five 16' stops and a total of about 50 speaking stops. It was the largest organ in the area. Indeed, it was a struggle to fit the organ into the church. The organ chamber included the entire front of the church, from the bottom of the basement to the top of the attic.

At the time the organ was built, there was a new interest in playing orchestral transcriptions on the organ. The Orchestral Organ, as championed by E. M. Skinner Organ Co of Boston, was built with special stops and voicing invented to imitate orchestral instruments. Under Palmer and Gibson's guidance, the St Pauls organ was designed as an orchestral organ. Of course, it could still fulfill the church functions of Hymn playing and choir accompanyment. But, with Lou Gibson at the keyboards, it could also do brilliant orchestral transcriptions.

GREAT ORGAN

- 16' Double Open Diapason

- 8' Open Diapason #1

- 8' Open Diapason #2

- 8' Stopped Diapason

- 8' Rohrflute

- 8' Dulciana

- 4' Principal

- 2-2/3' Octave Quint

- 2' Fifteenth

- 8' Trumpet

- Harp

- Chimes

SWELL ORGAN (enclosed)

- 16' Bourdon

- 8' Horn Diapason

- 8' Lieblich Gedeckt

- 8' Viola da Gamba

- 8' Voix Celeste

- 8' Dolce

- 4' Geigen Principal

- 4' Dolce Flute

- 2' Flautina

- IV Cornet

- 8' Cornopean

- 8' Oboe

- 8' Vox Humana

- Tremulant

- Harp

- Chimes

TUBA ORGAN (enclosed in Swell)

- 16' Contra Tuba

- 8' Tuba

- 4' Clarion

ORCHESTRAL ORGAN (enclosed)

- 16' Contra Viola

- 8' Violin Diapason

- 8' Viole d'Orchestre

- 8' Claribel Flute

- 8' Aeoline

- 4' Concert Flute

- 4' Viole Octaviante

- 2' Harmonic Piccolo

- 8' Clarinet

- Tremulant

- Harp

- Chimes

PEDAL ORGAN

- 32' Contra Bourdon (1-6 w/quints)

- 16' Open Metal (1-12 diaphone)

- 16' Open Wood

- 16' Bourdon

- 16' Violone (CH)

- 16' Gedeckt (SW)

- 8' Octave

- 8' Principal

- 8' Flute

- 8' Violoncello

- 16' Trombone

- Chimes

Keates Organ Company, late 1970's

About 1950, a house builder named Burt Keates decided he wanted to build organs. He attended the closing auction of the recently defunct Woodstock Organ Company, and won much of the old machinery and inventory (thereby carrying on some of the Warren/Woodstock legacy). He was also able to convince the Woodstock console maker, chest maker and perhaps others, to join him. By 1977, he had built Keates to be a company with about 14 employees.

By the 1960's the St Pauls organ was showing its age. The organ tuner, Mel Willitts of Woodstock, reported the the leather valves in the organ had perished and needed replacing. A volunteer group of church members, headed by Ian McPhail, spent months in the basement of the church, replacing thousands of leather valves. They did a commendable job and saved the church thousands of dollars. However, the organ also had other problems that were beyond the abilities of the volunteers, so the church decided to call in professionals: The Keates Organ Company.

The Organ had a serious design fault; it was too big for the church. Everything was crammed on top of each other, so access was blocked to the mechanism, making it impossible to repair or even tune. The pipes were stacked on two levels, with half the pipes in the basement. Several of the chamber walls and the roof, were outside walls, which let in the winter cold. Tuning stability of pipes depends on the temperature. Warm pipes go flat. Heat rises so the winter, upstairs pipes were always flat and out of tune to the downstairs pipes. Also, Orchestral organs had gone out of favour.

Keates' proposal was simple; remove the excess pipework and mechanism, and move the basement pipework and chests upstairs so all the pipes would be on the same level/temperature/tuning. This would also improve accessability. The result was that much of the orchestral pipework was lost, and the remaining pipework was rearranged, revoiced and/or repitched in an attempt to make a more classical church organ. That failed, because the remaining pipework was still orchestral and did classical music poorly; and yet the organ was now ruined for doing transcriptions. Lou Gibson was heartbroken and soon resigned. However, it is still a great organ that does a good job leading hymns and accompanying the choir.

Keates also replaced the drawknobs and Coupler tabs of the console, but didn't replace any of the switching.

GREAT ORGAN

- 16' Open Diapason (former Gt 2nd Open)

- 8' Stopped Diapason(1-18 Sw Bour 16,+ Ch Claribel Fl)

- 4' Principal (Sw Horn Diapason 8')

- 4' Rohrflute (was 8', stopped metal, Lieblich)

- 2-2/3' Quinte

- 2' Fifteenth

- IV Mixture (Made from cutdown strings)

- 8' Trumpet Former Tuba 8'

- Chimes

- Super

SWELL ORGAN

- 8' Lieblich Gedeckt (was 8' Gt Stopped Diapason)

- 8' Viola da Gamba

- 8' Voix Celeste (was Ch 4' Viole)

- 4' Geigen Principal

- 4' Dolce Flute (1-12 stopped wood, 13+ open metal)

- 2' Flautino

- III Plein Jeu III (Keates - new pipes)

- 8' Cornopean (#30+ harmonic)

- 8' Oboe

- Tremulant

- Sub Coupler

- Super Coupler

CHOIR (was ORCHESTRAL)

- 16' Contra Viola (unit chest for 1-32)

- 8' Gedeckt

- 8' Dulciana

- 8' Unda Maris

- 4' Octave

- 4' Concert Flute

- 2-2/3 Nasat

- 2' Harmonic Piccolo

- 8' Clarinet

- Tremulant

- Sub Coupler

- Super Coupler

PEDAL

- 32' Resultant

- 16' Open Metal

- 16' Bourdon

- 16' Violone (from Choir)

- 8' Octave

- 8' Flute

- 4' Choral Bass

- 2-2/3' Rauschpfeife IV

Blair Batty and Associates, Inc, Organbuilder

Blair Batty has been tuning and caring for the organ for about the past 30 years. By 1999(?), the 75 year old electrical switching system of the organ was no longer reliable. Also, much of the wire used was insulated by (inflammable) cotton wrapping.

So Blair replaced all the electrical control switching and wire with a modern system. This included a MIDI system allowing the organist to integrate other electronic music devices. The main bellows leather had deteriated after 75 years, so the bellows was releathered. Numerious other small problems were also fixed during the refurbishment. Many windchest electromagnets were also replaced.

About 2008, the pouch leather (which was now about 45 years old) was again worn out and leaking. Because this was causing dead notes, Mr Batty replaced the thousands of pouches. The accompanying photo shows pouch releathering.